Construction

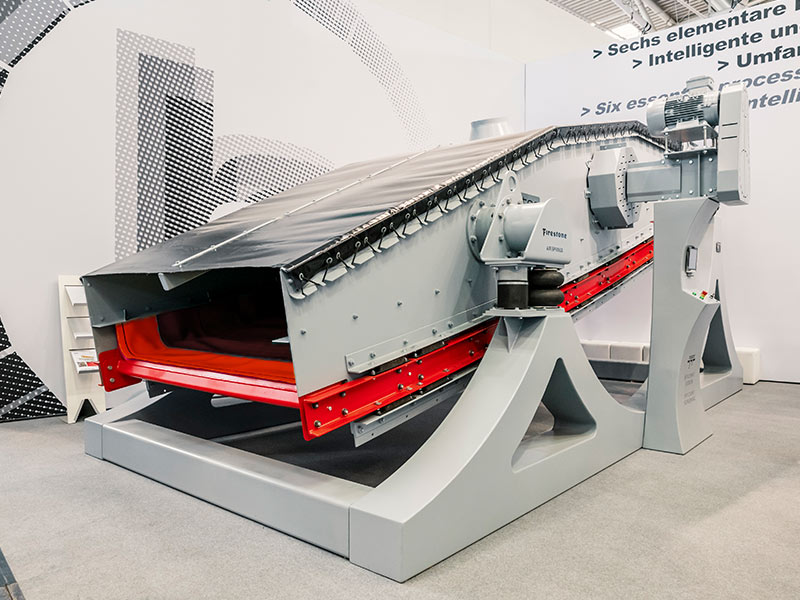

Dirty, dusty and wet operations make for daunting conditions ripe for rust and corrosion. Instead of waiting for parts to break, products like Marsh Mellow™ were made to protect them. Delivering superior vibration isolation, this variable-rate spring is a sealed unit designed to expertly handle differences in load.